-

Content count

1,128 -

Joined

-

Last visited

-

Days Won

5

Posts posted by Russ Johnson

-

-

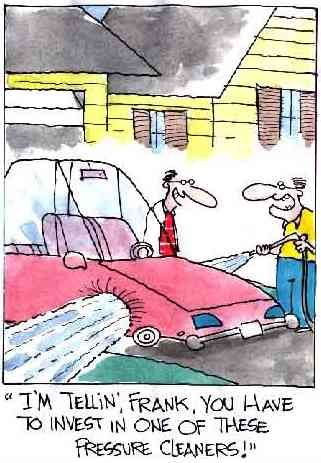

This is the only other pw cartoon I've seen...

-

-

I used 600# of sand on 2 chairs and the glider. 100# will last about 15 min. with 4 gpm.

-

Is your gauge mounted in a BYPASS port? It won't read anything if it is.

-

The 30005 should have a TS2021 General Pump on it.

-

Yeah...I did a glider, too, but I strapped it to a pallet first...

[YT]Qmw66s8B5sk[/YT]

-

[YT]R0PvkI2BADo[/YT]

This is a video of me sandblasting a steel chair. It's a piece of cake. "Rust Ban" will prevent flash rusting and can be painted over without further cleaning or rinsing.

You'll notice in the video, the sand inlet hose is always held above the nozzle and the gun is rested with the nozzle in a downward position. This keeps water from tricklin back into the sand hose. If the sand gets wet, it won't draw.

This is the "medium duty" kit from Ultimate Washer, but can be had for less.

It's all you'd need for occasional use.

-

If you are getting fuel to the solenoid valve, but none comes through, it could be one of several things. Firstly, take the coil off the solenoid (remove the little nut and slide it up off the post. Get a magnet, start the machine, turn the burner on, and slide the magnet along the post on the valve. If it fires' the valve itself is ok. Next, open the ignitor. Find the wires to the solenoid. One should be bundled in with a wire fron the ignitor and a wire from the motor. The other wire should be attached to only one wire. Remove the single wire and bundle it with the other wire going to the ignitor and motor (not the same bundle as the first solenoid wire). Cap all connections, close the ignitor, start the machine, and turn on the burner. If it lights, all is well with the burner assembly. Rewire everything back where it was and close the ignitor.

Now we have to go after the switches. Pressure switch, flow switch, vac switch, high limit switch, and / or thermostat. Bypassing a switch involves disconnecting the wiring going to a switch and connecting the wires that the switch was connected to together. Do them one at a time, rewiring properly before continuing to the next. A thermostat is the easiest. If you have a jumper wire with alligator clips, just clip the wire between the terminals. After bypassing each switch, do a test fire until you trace it down.

Or drive to Louisville and see me...

-

I wonder if it comes in drums?...

-

I'm going to be 92...enough time for me to be a burden to my children...

-

5 gpm, 3,000 psi = 10 hp electric

10 hp electric =

230 v, 1 ph - 45 amps

230 v, 3 ph - 27 amps

460 v, 3 ph - 14 amps

major power requirements...

-

Hey, ron p, how ya been?

-

The only way you could run a 12 volt burner is with a constantly charged battery. So, you need either an engine with a 20 amp charging system, or you hook it to your truck battery and leave the truck running while you're using hot water.

Propane is self contained, no outside power source is needed. You'll have to make sure you have reserve fuel, as it not as readily available as diesel.

120 volt requires you to buy a generator (2500 watt or larger), or get a huge extension cord to plug in at your customer's location (provided electricity is even available).

Wayne - Beckett...flip a coin. They both produce heat...that's about it.

-

The SC30008KAF is not set up to draw chems before the pump, but could be modified to do so. You would have to route your bypass back to the pump and install a chem valve on the suction side of the pump.

-

5.3 GPM won't net much flow per gun with 2 hooked up...need at least 8 or 9...2.6 GPM won't do much cleaning.

-

Yep..U bolts are great to fasten them down.

-

If you're shutting off the valve on the panel to stop soap,you're upstreaming the soap, and the only way to shut it off is at the panel. The dual lance wand would be used to control a downstream injector, which should be mounted in the outlet of your coil.

-

A propane fired heater has a "power pile" thermocouple. Basically, once you light the pilot, the thermocouple creates voltage to open and close the gas valve. The only drawback to this system is a ready supply of extra fuel. You need to make real sure you've got extra because LP is not as readily available as kerosene or diesel.

-

You could go propane and not need external power.

-

For speed, I'd use a Turbo...

-

"The results of the test were astonishing. I was able to remove all of the moss, lichens, algae and 20 years of dirt with the pressure washer. No damage whatsoever was done to the asphalt shingles"

See, you guys have been doing it wrong all along...lol

-

Welcome to the internets...

-

Must be bugs in the wood. We have carpenter bees here that will bore a 3/8" hole in wood (deck, fencepost, etc.). They go in a bit, then turn 90 degrees and bore out a tunnel to lay eggs. The woodpeckers can sense the larvae hatching out, and will tear the wood up the full length of the tunnel, leaving a 4" - 5" gash in the wood.

-

In case the inside of coil tubing is being refered to.....How often is subjective to amount of use. Unhook a line and see if there is any buildup on the inside of tubing. Might want to clean it with coil cleaner if it gets thicker then say a thin finger nail or if there is noticable flow differenece or noticable heating difference. Personally I just hook a flojet up as a loop and cycle about a 20% mixture of hydrochloric through for but a minute or two.Then I change the fluid out and do it again until it comes out clean. I follow up with a fresh water flush before hooking lines back up...

I hope you're buying "inhibited hydrochloric, or muriatic". Regular muriatic will eat iron...

I use a phosphoric mix that is used for descaling kitchen dishwashers...it's safe for the metals and does a really good job. Check a commercial kitchen or cleaning supplier for a source.

Is this a good deal?? Help!

in Residential Pressure Washing

Posted · Report reply

$14,474.60