-

Content count

1,128 -

Joined

-

Last visited

-

Days Won

5

Posts posted by Russ Johnson

-

-

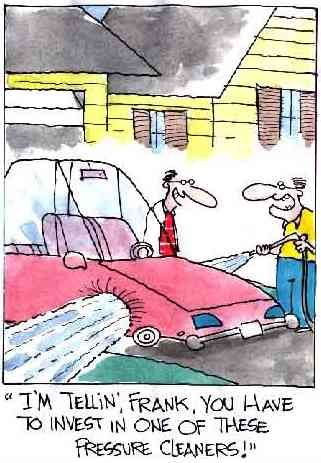

Take off your shirt, hold the power washer an inch away from one of your nipples, then turn the water on, full blast.You mean this isn't supposed to be fun???

-

Most of the time there are elongated holes in the pump rails. The bolts holding these need to be loosened. Many units have tensioners attached to the front of the rails by bolts which can be adjusted. Loosen the pump to the point that the belt goes on easily, then tighten to approximately 1/4" free play mid-pulleys. Thghten the pump bolts, and you're done.

You can also cheat and roll the belt over the edge of the pulley. Just make sure it doesn't twist.

-

Build your own and save some shipping money. 6' and above ship oversized. Get a 4' insulated lance, 2 - 3' aluminum bare lances, and 2 freight saver collars (1/4" coupling with deeply recessed threads), and there's a 10 footer...

-

Butyl degreasers will remove wood smoke residue.

-

Scott, try it with 100' of hose and see if it works. If it does, and you want to downstream through 200', you'll need a size smaller injector. Send it back and I'll send you a new one.

-

The replacement skirt is - $98.60. The clips and rivets are available as a unit. $1.61 each and you should need a total of 11.

-

The rivets holding the clips have to be drilled out to replace the brush ring. I believe the mounting kit comes with new clips and rivets... I'll check and let you know. For the stripped setscrews, I suggest taking the handle to a machine shop. If they can't get them out, they may be able to drill and tap to the next larger size. Any time you get dissimilar metals and water together, they tend to weld themselves together. When you replace them, try to find stainless setscrews and give them a light coat of Never-Sieze.

-

How much hose are you using? Do you have a reel? I've never actually tested a 20% injector....just took their word for it. Might have to hook one up and see. Hose back pressure shouldn't much matter as long as it's low enough to pull the ball fully out of the seat. If it's borderline, it may "flutter" and not pull true.

-

-

Maybe the liner out of a container lid? Like a gas can or chemical jug?

-

Maybe an Oberdorfer bronze gear pump?

-

I wouldn't waste my money. If you take a WELL INSULATED screwdriveer, contact one terminal and slide it toward the other, you should get 3/8" - 1/2" crackling blue arc. A short or lazy yellow arc indicate a transformer that is on its way out.

-

The ST-72 is a very nice piece of equipment Makes lots of foam with the right detergent.

-

That is EXTREMELY cool!

-

This breakdown shows the TS 1011, 1511, and 2011. The only differences are a nickel plated manifold and a crankcase cover.

http://www.generalpump.com/PDFs/TS1011-Pump.pdf

Are you sure it isn't a T1011? Those specs are the same as a TS2021.

-

The TS1011 has a 12 mm stroke, the TS2021 has a 16 mm stroke, both with 20 mm pistons, so a TS2021 will pump more water per revolution than a TS1011. The internal parts of the TS1011 are identical to the parts of a TS1511, rated at 4 gpm, 3,500 psi.

-

You'll need a lot of 1/4" hose, a sewer nozzle, the pulse device for the valve (can be done without), maybe a foot valve so you can keep both hands on the hose. Shouldn't be terribly expensive...I'll research it later and let you know. If your Tuff is a hot water, you'll do even better on greasy clogs.

-

Sure you can. They make a device that holds one of the valves open giving you a pulse type spray.

-

I have done that very thing. Set up a hot box to work in a pickup with a topper. Modified the frame, moved the fuel tank, and laid 'er down. No problems at all.

-

Very nice cleaner. I've heard no complaints whatsoever. The one thing about a Whirl-A-Way that is nice is the swivel has a grease fitting on it so you can maintain your bearings instead of just waiting for them to wear out. Had one customer ordered a WAW swivel to retrofit his Big Guy.

-

Why buy hose from your for $100 and have to wait a week for shipping if I can have it at my door from an online vendor in a week for $70?? You can't challenge the online guys on price,That's exactly why a supply business can't do extremely well concentrating sales to mobile washers. The guys in manufacturing plants, farms, auto and truck repair garages, etc. aren't as interested in saving so much as getting it NOW. That's why there's about $80,000 worth of inventory (pressure washers, parts, chemicals) in my shop. On line sellers, myself included, rely more on drop shipments from our suppliers. Cold water washers are another story altogether with Home Depot, Lowe's, Sam's Club, etc. working on narrow margins because of volume purchasing. A homeowner who calls looking for a price on one of them must be convinced that you have more to offer than the "big box".

The first thing a retailer must do is get a distributorship for a pressure washer manufacturer. The parts suppliers won't even talk to you unless you can prove you're a distributor.

Call me if you like, I could write here all day and not answer every question you have...502-231-6506...5:00-5:30 PM eastern time would be the best time to catch me for a sit down talk, otherwise I'll be holding the phone with my shoulder while I'm working.

-

-

An 8 gpm machine with a regulating unloader designed for 2 gun operation DOES decrease flow out the gun by reducing nozzle size. The unloader is made to run in partial bypass...so...if you set the unloader for 3,000 psi operating pressure, with a #9 nozzle, all 8 gpm's are coming through. Use a #4.5, and you have 4 gpm @ 3,000 psi at the gun. A hot water machine should never be "throttled back" because:

A) As was mentioned, the engine needs the air flow for cooling.

B) The engine's charging system won't make enough juice to keep the battery up on a 12 volt burner system.

C) With a 120 volt system, the generator requires proper rpm's to make 110 - 126 volts at 58 - 62 Hz.

So...with a regulating unloader and a thermostat, you can vary the flow at full pressure with a tip change.

PS...My vote is for Hydro Tek, too.

-

More than likely a "manufacturer's spec"...probably 4.8 gpm @ 2800 or so. Steve, what pump do you currently have on that machine? If you stick with the same manufacturer and rpm rating, you won't need to drill new holes, change pulleys and belts, etc.

If....

in The Club House

Posted · Report reply

How about a twist type nozzle holder with a QC mounted in it?